The title phrase seems utopian. How do we reduce stockouts and at the same time optimize inventories? How can this be achieved? First, let’s analyze the probable causes that lead us to have these shortages and excess inventories in a retail environment.

- In retail, the customer is not willing to wait. This is a vital premise in this type of channel. The customer enters a store and wants the products to be available. This creates pressure to have the inventory close to the customer, and therefore, the stockout is often a lost sale.

- Today, marketing and sales have increased the size of the portfolios facing the customer, seeking to give the customer more options, or it is the result of innovations within the business.

- With the increase in channels, the customer has more options to access the same product, which generates more pressure on the lost sale.

- In retail sales, there are more promotions, special days, clearance sales, etc., that generate high volatility in demand.

- Many of the products supplied in a retail sale originate in imported products with long delivery times or in locally manufactured products in which some of their inputs are imported. This generates the need to have forecasts for the future, at least in the horizon that covers the accumulated time from purchase to sale (in many cases this time can be up to 120 days or more), and as we saw in the previous points, having a volatile demand, with an increasingly larger portfolio, a forecast is increasingly less accurate, and the further and more detailed it is required, the worse it will be.

- There are conditions in the supply that impose restrictions such as minimum purchase quantities and amounts, rigid supply frequencies, difficulties in entering urban areas in large vehicles, cut-off dates for perishable products, etc.

- Inventory policies tied to maximums and minimums reviewed with low frequency

- Exhibits tied to aesthetic product presentation decisions without real consideration of rotation.

- Purchasing teams with thousands of combinations (item – warehouse) to analyze that in many cases end up being analyzed in Excel with information disconnected from the different sources.

- Supply decisions dependent on the administrators of the points of sale, which often correspond more to panic supplies or inventory hoarding than to sensible decisions.

These are some of the probable causes that mean that in the end, at the final point of sale, there is an inventory that is not aligned with real demand, resulting in shortages and excesses.

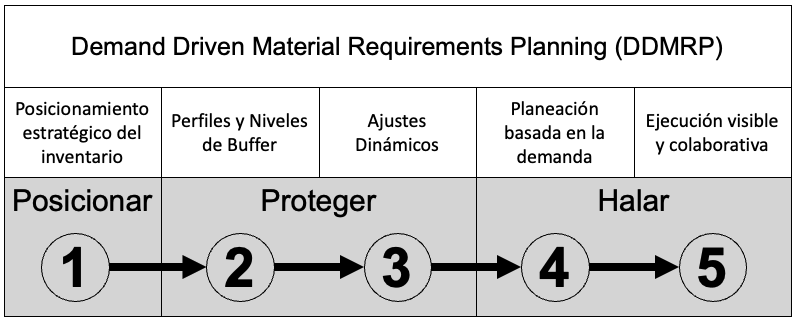

The DDMRP methodology developed by Carol Ptak and Chad Smith takes many of the concepts of supply chain, ECR, Lean, TOC, MRP, DRP and creates a model to position, protect and pull inventory from real demand. It seeks to protect and promote the flow of relevant information and materials.

How does DDMRP help mitigate the causes described previously? Let’s start by following the steps proposed by the methodology.

Step 1. Strategic positioning of inventory.

In this step, you must select which is the portfolio and where it should be positioned. The activities that must be carried out at this point are:

- Portfolio analysis (not all the portfolio applies to all regions and points of sale) and this analysis should not only validate commercial and marketing issues but also take into account the rotation information against real demand

- The points of greatest inventory leverage must be identified (the points in which the greatest consolidation of this is achieved and/or proximity to the source). We have the notion that having the inventory close to the customer will have the greatest benefits, but while we have the greatest amount of inventory close to the customer, we will have the place where it is most expensive to store it and at the same time the point that is subject to the greatest variability of demand.

Step 2 and 3 – Dynamic dimensioning of inventory.

These steps are vital to correctly dimension the appropriate inventory level for real or expected demand. There are several factors that affect it and that will always be susceptible to improvement such as frequency of review of the suggested, frequency of supply, delivery time, packaging units, reliability of suppliers. All these factors are crucial when dimensioning the size and affect it, but the methodology directly shows the impact of the decisions. Several issues should also be specifically analyzed in Retail:

- The more frequent the replenishment, the less inventory is required at the destination. The design of centralized supply facilitates the increase in frequency. In order to increase the frequency, the company must also work on efficient material management models (barcode management, RFID, WMS, efficient picking, etc.).

- Many times the quantities that the model suggests to maintain at the points of sale is less than what the administrators of the point of sale would like or less than what the visual or exhibition desires. This point is one of the most critical and requires in many cases managerial participation because the type of portfolio to have in the stores is questioned, the success of some products or not, the possible de-codification of articles. In many cases, more products displayed is not equivalent to more sales… in many cases less products is more sales.

- The information of the extraordinary demand in the short term is vital. In-Out, promotions, price changes, introduction of new products, collections, etc. the information that should be received from the forecast changes; short term detailed in events, long term aggregated for purchases and capacity analysis.

- In fashion companies, two cycles must be identified, one associated with launch dates (MTO) and another associated with inventory replenishment (MTS).

- In these steps 2 and 3, statistical, probabilistic or artificial intelligence models can help to have more adequate information of the real/expected demand and in combination with the previous parameters generate a correct dimensioning for each combination of SKU-Position. However, our recommendation is that first you have to know the demand very well with simple models and then go forward in the automation of it.

Step 4 Demand-driven planning.

In this step, the way the suggested is calculated changes, it is no longer as it is commonly done, forecast vs inventory policy or under suggestions from the administrator. It is done taking into account the real demand. In this step, the model takes into account the restrictions such as minimum purchase in money and/or quantity, minimum transport, optimization of freights, scarcity in origin (quantity and/or capacity). Depending on the company, the model can operate iteratively complying with the previous restrictions and facilitating the planner with the suggestions that comply with the best option Flow – Cost.

Step 5. Visible and Collaborative Execution.

When the organization has defined that the priority is to minimize the stockout of the product without excess inventory, the execution must be aligned to it. The methodology provides the visibility so that all those who are in the execution (purchases, storage, shipments, transport) are aligned to protect the availability. Priority schemes based on dates change dramatically and therefore a newly issued order may be more urgent than an order issued previously, all because the demand requires it.

Preparing the change. The implementation of these steps requires that several elements are met within the organization:

- The managerial will to define the availability of inventory as a strategic priority

- A specific design for each business, the conditions of product, portfolio, supply, product, are unique for each business

- Education in the principles of supply chain, ECR and DDMRP are vital.

- Participation of Marketing, Sales and Finance, hopefully with an active Sales and Operations planning process, where a review of the integrated portfolio, sales, supply and financial plans is carried out.

- Periodic review of the design parameters of the model, the conditions of demand, variability, suppliers change and therefore the design must be reviewed and adjusted continuously to the new conditions.

- Change management, because many of the traditional activities based on cost optimization, negotiation, exhibition, can be challenged by the model. The relationship of sales / invested capital must be understood.

- Information systems that allow to have reliable and agile information from the point of sale (POS), transactional information (Customer orders, transfers, inventories, open purchase orders, manufacturing orders)

- Software that allows planning under the methodology, because specifically in Retail the amount of combinations to do it in Excel is complex.