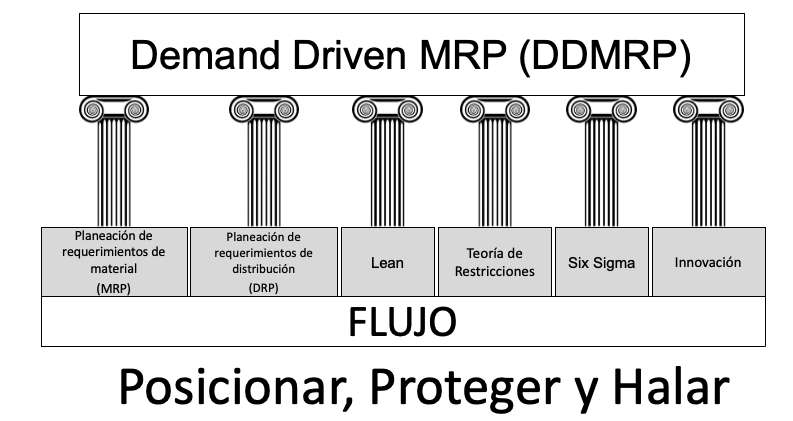

DDMRP is a method for modeling, planning, and managing supply chains to protect and promote the flow of relevant information and materials. DDMRP is the management and supply order generation engine of a demand-driven operating model (DDOM).

The Demand Driven operating model is the generation of replenishment orders, production scheduling, and the execution model, using actual demand along with strategic decoupling, control points, and inventory, time, and capacity buffers, to create a predictable and agile system that promotes and protects the flow of relevant information and materials within the relevant operational-tactical range (hour, day, and week).

The key parameters of the Demand Driven operating model are established through the sales and operations planning process to meet the established business and market objectives, minimizing working capital and expenses related to emergencies.

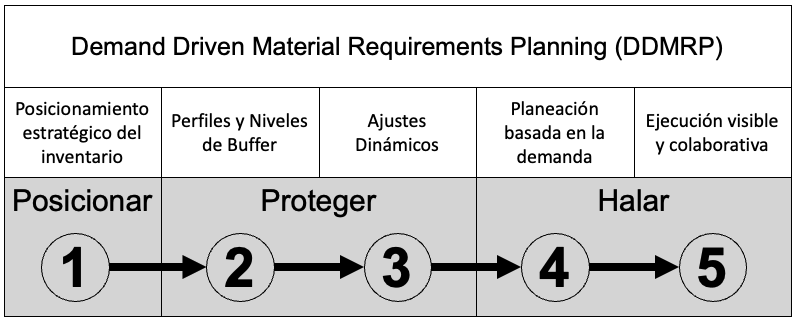

DDMRP has 5 Components

DDMRP Components – Copyright Demand Driven Institute

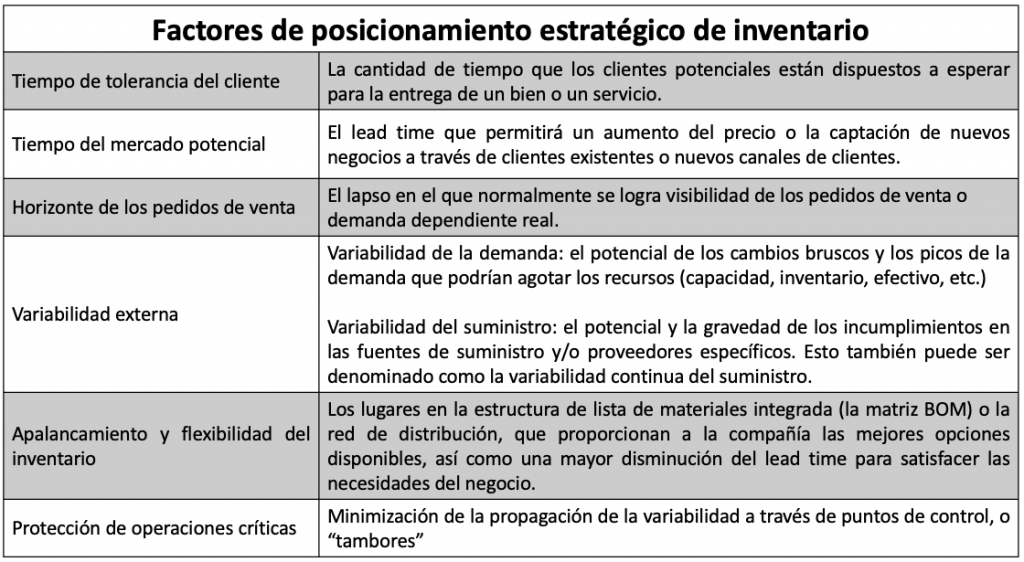

Step 1 – Strategic Inventory Positioning. Decoupling points are strategically located to decouple variability and shorten delivery time. There are 6 factors for positioning these decoupling points.

Positioning Factors – Copyright Demand Driven Institute

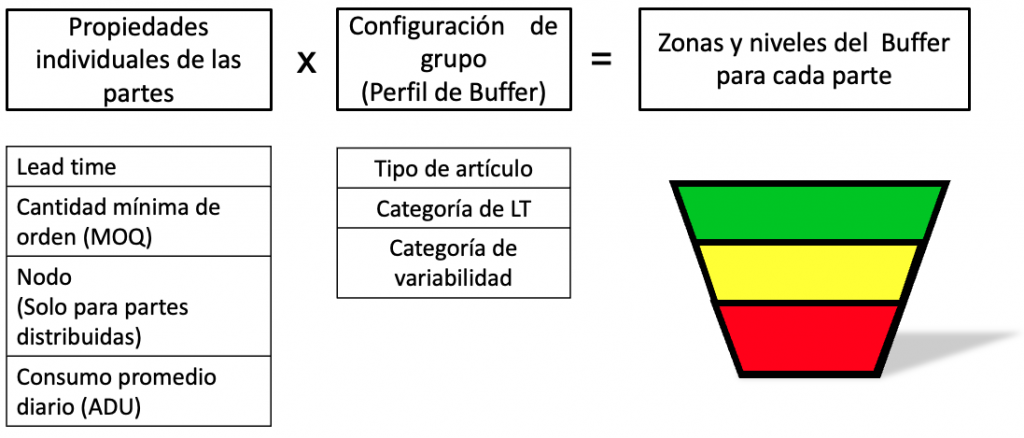

Step 2 – Buffer Profiles and Levels. For each SKU – Position, a unique Buffer size is calculated that depends on group properties and individual properties.

Buffer Profiles and Levels – Copyright Demand Driven Institute

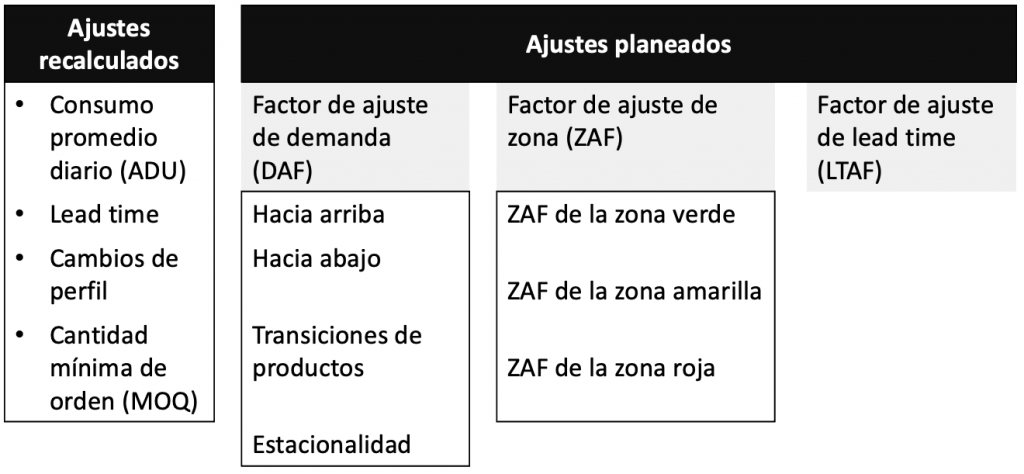

Step 3 – Dynamic Adjustments. DDMRP dynamically adjusts the buffers, taking into account history (ADU, Parameter Changes) and the future (Planned Adjustments). Generating a robust model that adjusts to protect the flow.

Dynamic Adjustments – Copyright Demand Driven Institute

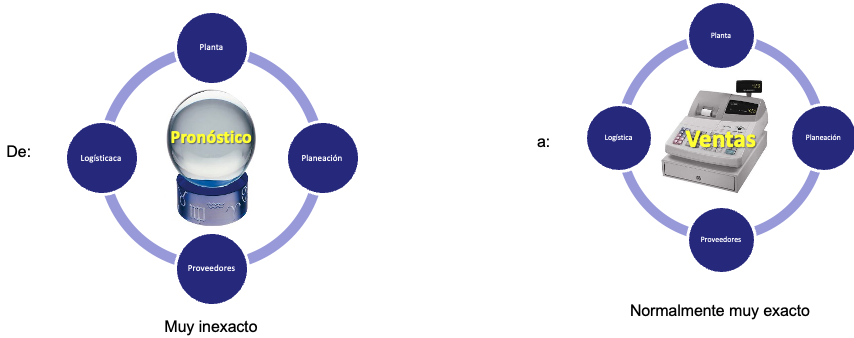

Step 4 – Demand Driven Planning. DDMRP introduces the innovation of Net Flow, which takes into account available inventory + orders in transit – the dispatches of the day – relevant future demand. Using more accurate and relevant information for the generation of orders, the actual demand.

Demand Driven Planning – Copyright Demand Driven Institute

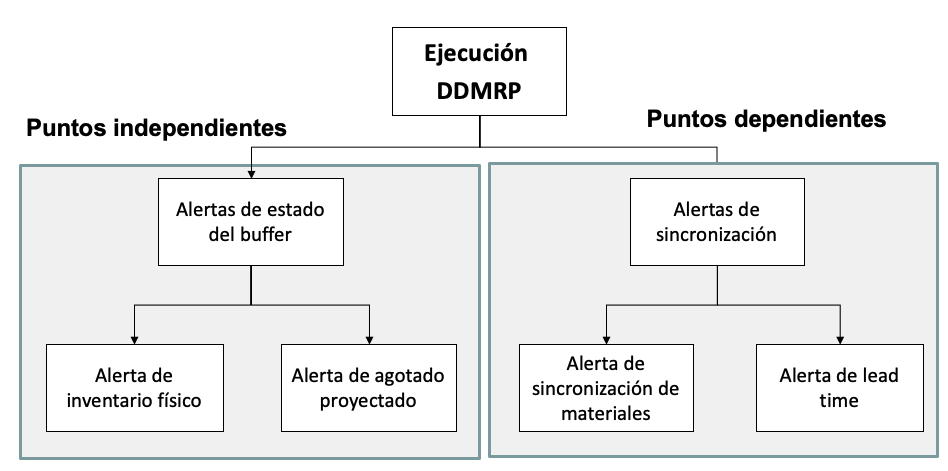

Step 5 – Visible and Collaborative Execution. DDMRP provides the relative priority that allows the team that executes to clearly have the priorities. The traditional model of prioritizing by date does not necessarily guarantee being aligned with availability needs.